October 24, 2019

When & Where Offsite Construction Technologies Will Emerge

During a presentation at NAHB’s 2019 Building Systems Housing Summit in October, Ed Hudson, Home Innovation Research Labs Director, Market Research, provided insight as to when and where he believes offsite construction technologies are likely to have an impact in the coming years. The data presented were from a survey of home builders Home Innovation conducted in August 2019.

In the survey, four questions were asked on the topic of offsite housing technologies: two asking builders what offsite methods they anticipate using one and five years from now; one on barriers to using these technologies; and a final one seeking to understand the role labor played in their decisions regarding offsite housing. A summary of Ed’s presentation is below; you can also download the entire presentation.

FUTURE USE OF OFFSITE TECHNOLOGIES

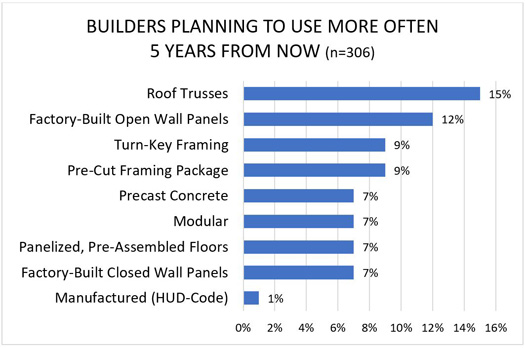

Looking to the future, builders anticipate using offsite construction methods, particularly Roof Trusses and Open Wall Panels, more often. Modular and Pre-Assembled Floors were also expected to be a more common part of builders’ standard practice. Respondents said they were least interested in Manufactured, or HUD-Code, Homes. See more details in the chart below.

Source: Home Innovation Research Labs, August 2019 Survey of Home Builders

For most offsite construction practices, Production Builders were 2 to 3 times more likely to increase their use compared to Custom Builders. Likewise, Townhouse and Multifamily Builders were far more likely to increase their use of offsite practices than were Single-Family builders. No difference was observed in future use based on the price-point of home construction—i.e., Starter, Move-up, or Luxury.

BARRIERS TO ADOPTING OFFSITE

“Considering your company’s decision to use (or not use) pre-fabricated building systems and components, what role does the availability of construction labor play in that decision? Please explain.”

Builders gave a wide variety of perspectives on this survey question regarding barriers to offsite technology use. The vast majority of responses fit into the following categories:

- None—already use them

- No reason to change—what we’re doing now works fine

- Unaware of the options

- Need trustworthy local sources

- Believe offsite technologies cost more than site-built

- Workforce is unwilling/unable to change

- It takes time & effort to change—too busy at the moment

- Offsite alternatives require extensive pre-planning & long wait times for delivery

- Have issues with local logistics for delivery, access to the site, or shipping

- There’s a negative perception of offsite in their market—homeowners see it as lower quality

- Can’t accommodate last-minute changes in home construction with offsite technologies

POSSIBLE WAYS TO OVERCOME THESE BARRIERS

Ed concluded his presentation by going over some potential strategies and practices that offsite housing producers might consider to mitigate these barriers, including:

- Offer a turnkey materials-and-installation service—whether integrating upstream or downstream of their current operation

- Create a decentralized production strategy—many smaller producers with local market service to keep transportation costs lower and provide needed technical support

- Provide system, equipment, software, and know-how to larger builders so they can create their own offsite solution

- Provide training for local framers—eliminate one labor issue and create pull-through demand

- Use 3-D modeling/BIM and virtual reality so homebuyers can better evaluate plans, reducing need for last-minute homebuyer modifications

Ed and other members of the Home Innovation team are frequently called upon to share insights with various industry groups. If you’re interested in finding out more about the data presented above, purchasing your own survey data reports, or enlisting Ed to present at your industry conference, get in touch.

Back to Top