October 23, 2020

Strategies to Save on the High Cost of Lumber

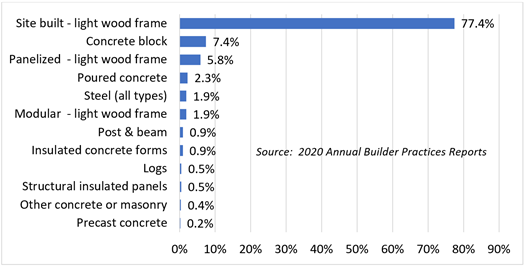

With lumber prices soaring in the past several months, home builders are scrambling for ways to keep the cost of construction in check, fueling a renewed interest in alternative materials. While they may still not be cheaper than lumber, the spike in lumber prices is causing many builders to rethink the cost/benefit tradeoffs of traditional alternatives to lumber — steel, concrete, and plastics.

In early October 2020, Ed Hudson, Home Innovation’s Director, Market Research, presented a trend summary of alternatives to lumber in a private videoconference meeting of home builders. The full presentation can be found on our website.

Source: September 2020 Builders Survey, Home Innovation

Advanced Framing—Just Use Less Lumber

In the Lumber Alternatives presentation, the first option discussed was a simple concept—continue building the same houses, just using less lumber. “Advanced Framing” methods, which conserve lumber and boost home energy efficiency, are not new and have been code-approved for decades. (You can see Home Innovation reports related to advanced framing over the years on our website.) They are popular in some factory-built housing types, but they have not become mainstream for site-built homes due to several factors.

First, with the relatively low prices for lumber historically, there has been little incentive for changing framing methods to conserve lumber. The adage, “If it ain’t broke, don’t fix it,” comes to mind. Second, and perhaps more significantly, the longstanding shortage of experienced framing labor within the construction industry has fortified the inertia regarding conventional framing practices.

One word of caution to builders when considering advanced framing techniques: be sure to think through the impact of having less lumber in homes, particularly as it relates to the attachment of finish materials such as siding, trim, wallboard, flooring, etc. For example, wider spacing of floor joists may allow too much flex for tile floors, while it may be quite acceptable for resilient flooring.

Alternatives to Dimensional Lumber

Another option covered in the presentation was lumber savings through more extensive use of engineered lumber and pre-fabricated building components that use less wood fiber than dimensional lumber. Trusses can be used for roof framing in place of solid dimensional rafter and ceiling joists (which represented a third of roof structures in 2019). In floors, the option of engineered wood I-joists or floor trusses can replace 2x10s and 2x12s. Another option in some situations is substituting a concrete slab floor on the main living level in place of lumber joist floors.

In above-grade walls, opportunities exist to substitute for lumber, but generally, these require greater building process change to implement. Poured concrete, concrete block, ICFs, and light and heavy gauge steel systems are ubiquitous in commercial construction, and have been gaining renewed interest in homes as lumber prices remain elevated. For builders already constructing concrete basement, crawlspace, or slab-on-stemwall foundations for their homes, a switch to concrete materials for above-grade walls may be a more natural step with continuing the foundation wall to the roof.

Another option for conserving lumber is the structural insulated panels, or “ SIPs,” for walls and, potentially, floors and roof applications, as well. Galvanized, cold-formed steel framing gained popularity in homes a couple decades ago but lost steam primarily due to its higher price relative to lumber — that’s not the case in today’s market. Light-gauge steel for interior partition wall framing is perhaps the easiest-to-implement option.

For outdoor structures like decks and porches that rely on lumber, there are numerous options. One is to forego the raised porch or deck for an on-grade porch or patio using poured concrete, pavers, brick, or stone as the surfacing material. If going on-grade is not an option, then there are many alternative to lumber decking, such as plastic composites, PVC, and aluminum.

Stay Tuned…

The 2021 Builder Practices Survey will be fielded in November, and the findings are expected to be available as early as February 2021. We anticipate seeing aspects of Advanced Framing growing in popularity throughout 2020, and expect to see engineered wood and factory-built component shares to rise, as well. Steel framing, particularly in interior walls, will likely also reflect the rising price of lumber with an increase in share. And composites are likely to gain against lumber in decking applications.

Interested in more info on how the industry is dealing with increased lumber costs? What trends we’re seeing? Or how you might be able to provide viable solutions? Contact Ed to discuss our outlook and specific growth opportunities for the products and materials your company supplies or manufactures.

Back to Top