Damiyen Wilkerson

December 21, 2023

The Ins and Outs of Grade I Insulation

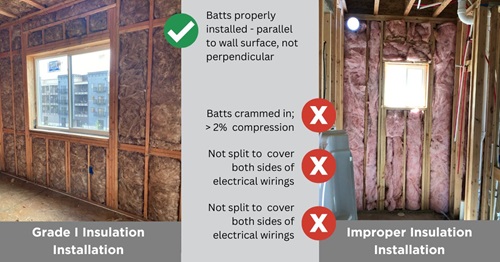

Grade I insulation is a common term used widely by building professionals; however, how Grade I is defined varies considerably among building professionals. At its core, the term is meant to construe that the home’s insulation is installed properly and will be as effective as possible based on the properties of the material.

While insulation installation may seem straightforward, we often hear that builders, contractors, and insulation subcontractors have difficulty achieving true Grade I insulation, regardless of the type of building. The National Green Building Standard ICC-700 requires that building insulation installation be inspected and rated by an accredited third-party NGBS Green Verifier. These verifiers are essential to ensuring the quality of the homes built and identifying issues that can be addressed prior to drywall installation. Fiberglass batt insulation, as our verifiers have noted, is often the most difficult to install to Grade I.

Grade I Insulation – As Defined by the National Green Building Standard ICC-700

The National Green Building Standard ICC-700 clearly defines Grade I insulation installation using the following parameters:

- Inspection is conducted before insulation is covered.

- Air-permeable insulation (i.e. fiberglass batt) is enclosed on all six sides and is in substantial contact with the sheathing material on one or more sides (interior or exterior) of the cavity. Air permeable insulation in ceilings is not required to be enclosed when the insulation is installed in substantial contact with the surfaces it is intended to insulate.

- Cavity insulation uniformly fills each cavity side-to-side and top-to-bottom, without substantial gaps or voids around obstructions (such as blocking or bridging).

- Cavity insulation compression or incomplete fill amounts to 2% or less, presuming the compressed or incomplete areas are a minimum of 70% of the intended fill thickness; occasional small gaps are acceptable.

- Exterior rigid insulation has substantial contact with the structural framing members or sheathing materials and is tightly fitted at joints.

- Cavity insulation is split, installed, and/or fitted tightly around wiring and other services.

- Exterior sheathing is not visible from the interior through gaps in the cavity insulation.

- Faced batt insulation is permitted to have side-stapled tabs, provided the tabs are stapled neatly with no buckling, and provided the batt is compressed only at the edges of each cavity, to the depth of the tab itself.

- Where properly installed, ICFs, SIPs, and other wall systems that provide integral insulation are deemed in compliance with this section.

The Importance of Proper Insulation

Properly installing insulation not only creates a more energy efficient home, but also improves soundproofing, moisture control, and overall comfort. Further long-term benefits of correctly installed insulation can include savings on utility bills and maintaining or enhancing property value. Hiring qualified professionals and following best practices during insulation installation is crucial to reap these benefits. A cornerstone of NGBS Green certification is that every building is inspected by an Accredited Verifier to ensure that insulation is installed correctly. The insulation inspection is merely one of dozens of green practices that the Verifier will visually inspect before any building can earn NGBS Green certification.

Interested in learning more about the value of NGBS Green certification? Contact us!

Back to Top