Recently, I shared results from our builder survey on foam wall sheathing and how its use varied by builder type, price point and type of home, and geographic areas. Now I’d like to share a few things we learned about usage patterns in thickness of foam sheathing in the same survey.

Overall, there are more builders reporting installing thicker foam (60%) on their homes than thinner (40%). And, interestingly, colder climate alone does not seem to dictate when a thicker foam is used by builders. Our findings infer that foam’s impact on cost and construction complexity may play as big a role as climate, if not an even bigger role, when it comes to selecting foam thickness. Because thicker foams typically add more cost and complexity to building construction, the more cost-conscious builders and those with highest annual outputs, lean toward thinner foam; some of these builders avoid the thickest foam completely.

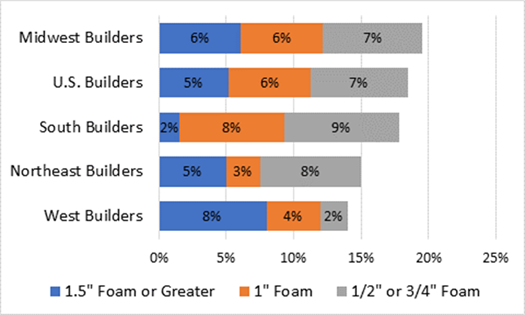

Regional Differences in Foam Thickness Used

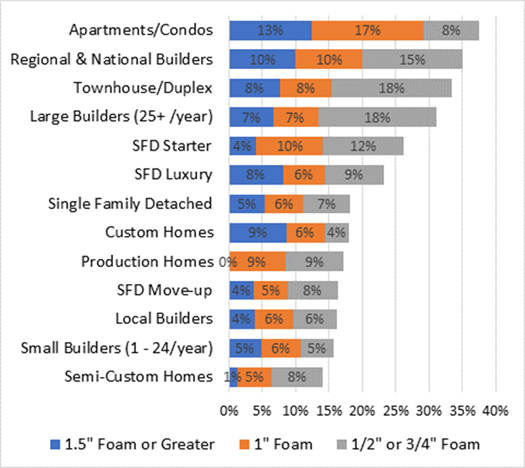

Differences in Foam Usage Based on Builder Type

Thinner foam (< 1") usage is most popular among those identifying as regional/national builders, starter home builders, large builders, and townhouse builders. The builders typically have high production businesses, with a heavier concentration on lower price-point homes. Thin foam is least popular among custom home builders and those who build in the West. Construction cycle time and cost play a smaller role in custom homes than production homes.

Regionally, thicker foam usage observed in the West is driven by two factors—cold climate areas of the North and higher elevations. It is also customary in many areas where stucco is popular, such as in the West, to use a thicker EPS foam board as a base for stucco—it’s believed to reduce cracking, especially under one-coat stucco applications.

Thickest foam (>1.5") is most popular in custom homes and homes built in the West. Nearly half of builders who report building custom homes use 1.5" foam or thicker. Climate likely plays a role in the South, with only about one-eighth of builders using 1.5" foam sheathing; meanwhile, at least a third of builders in the Northeast and Midwest report using 1.5" or thicker foam.

The findings of this research certainly confirm that climate plays a role in which insulation products builders choose. But what is more interesting for product manufacturers, is that the findings also signal opportunities for those who can create lower-cost foam solutions that are easier to install.

For more information on the results of this survey, or others that are specific to your business, contact us.