I often hear comments from building material suppliers that home builders are completely driven by cost. My years of marketing research among building professionals have taught me that this assertion is only partially correct. Cost is very important to builders, but only as compared to the benefits provided. Successful builders and remodelers are often willing to pay more where superior value is demonstrated.

This premise holds true across most decision areas for builders, including the decisions builders are now making, either by choice or by mandate, to help reach higher R-values in the building envelope of the homes they build. While some improvements in home energy efficiency may be as simple as specifying higher efficiency equipment or material, increasing R-value of walls often means changes in home dimensions and construction detailing that add time, cost, and risk to building a home. The most popular options available at the present are addressing the size of the wall framing — such as switching from 2 x 4 to 2 x 6 walls; installing foam insulation board on exterior walls; and using an insulation material with a substantially higher R-value per inch, such as spray polyurethane foam (SPF).

Home Innovation Research Labs has been tracking wall configuration and materials used for the past 15 years through our Annual Builder Practices Survey (ABPS). Of the above-mentioned alternatives for increasing wall R-values, 2 x 6 and deeper walls are the most popular. Nearly 40 percent of all new home walls use 2 x 6 framing or larger — up from about 30 percent only five years ago. In the most northern latitudes of the United States, 2 x 6 wall framing is now standard, and this trend is moving south. Not many builders doing this option are currently taking advantage of code-permitted 24” on-center spacing for 2 x 6s to help offset the higher cost of framing and insulation. Probably the least-costly of the common alternatives for increasing R-value, 2 x 6 framing typically requires some redesign and re-specification for homes whose plans call for 2 x 4 walls, but is otherwise fairly easy to implement.

Second in popularity is foam board on exterior walls—now on about 15 percent of all new homes and relatively unchanged over the past several years—about 6 percent with foam attached directly to wall studs and 9 percent as a 2nd layer on (or under) plywood or OSB wall sheathing according to the ABPS. With foam board on the exterior, builders can retain their 2 x 4 framing but sometimes exterior detailing and attachment methods need to be altered. The benefits of “continuous” exterior wall insulation with foam board are increasingly well known.

The third most popular alternative for increasing wall R-value is spray polyurethane foam (SPF), which is now in about 11 percent of all new homes, up from about 3 percent five years earlier. SPF has an R-value of up to 6.5 per inch compared to about R-4.3 per inch for the denser fiberglass batts so builders can get R-19 or higher in 2 x 4 walls. Despite the increase in cost for SPF, the additional benefits of air sealing wall cavities have helped make it a popular and quickly-growing alternative.

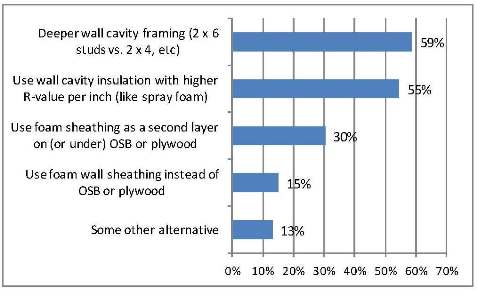

While these past trends are helpful in understanding where we are today, and perhaps how we arrived here, we can’t rely completely on the past to predict the future of wall construction. To help us understand where the market is going, we recently conducted a survey of U.S. new home builders and asked which alternatives they would choose if increasing R-value in exterior walls (multiple answers were accepted).

How Builders Plan to Increase R-value in Exterior Walls

The second most popular response — higher R-value insulation—is another example that higher-cost alternatives can be viable as long as they have a corresponding increase in value to the builder or homebuyer. Builders cite the benefits of expanding foam’s higher R-value and ability to penetrate and fill gaps for an air-tight envelope, which are easy to explain or demonstrate to homebuyers.

The third most popular option is foam sheathing, attached either on top or under OSB or plywood. Thirty percent of builders chose this as an option for increasing R-value in walls. Two layers of sheathing has a higher material and labor cost than a single layer in most situations, but the combination of strength and insulation is enough to keep this option a popular one. The least popular of the four options is foam wall sheathing as a substitute for plywood or OSB sheathing, with only 15 percent of builders choosing it.

These examples are reminders that the higher-cost systems with readily apparent, highly-valued benefits are often chosen over lower-cost options with ambiguous benefits. Success in providing value-added alternatives in home construction requires understanding the benefits valued by builders and homebuyers and then clearly communicating these benefits.

This is just a snapshot of one small piece of our available survey data. If you're interested in exploring and maximizing your product's value proposition among builders seeking solutions to increasing code requirements, let me know. I'd love to discuss ways we can help you uncover what about your product or material is truly valuable to builders.

***